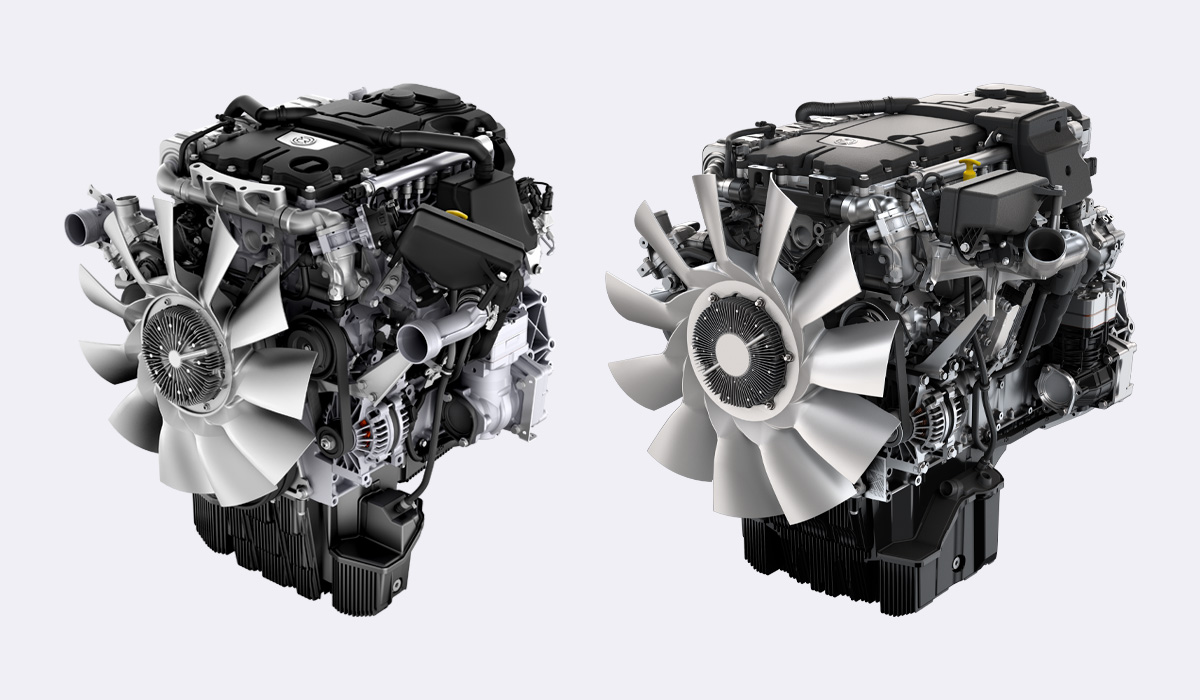

DD5 and DD8 Engines Eliminate Park Regeneration

The Detroit® DD5™ and DD8™ engines are specifically designed as industry workhorses, with reduced downtime accomplished through extended oil change intervals, variable cam phasing, a cracked rod process to improve piston rod tolerance and more.

“The engines are used in slow-moving vehicles, like trash trucks or school buses, which average about 20 mph and have frequent stops. When moving at slower speeds, a lot of particulate matter backs up into the system,” says Mark Gibson, Truck Sales, Johnson Truck Center, a member of Indel Power Group. “With variable cam phasing, the timing adjusts and the exhaust valves are opened earlier, pushing the warm exhaust and particulate matter to the after-treatment system.”

The DD5 and DD8 after-treatment technology improves the whole system by reducing the particulate buildup, increasing engine oil change intervals to 35,000 miles, and saving customers time and money by eliminating the need for park regeneration, which can take 45 minutes to an hour while operators wait for the filter to clean out. “A trash truck that requires no regen really stands out, and it contributes to a very efficient operation,” says Gibson.

Lee Hall, Fleet Manager for the City of Fairfax, Virginia, has two, Freightliner refuse collectors with the DD8 engine. During fiscal year 2021, he tracked comparison data for his two trucks with DD8s against two Mack trucks with another engine brand. Among the four trucks, they all registered comparable mileage, but his average fuel costs were cut almost in half with the DD8-engine trucks. In addition, his overall operational costs, including fuel, labor, parts, warranty credits, etc., were reduced by about $7,000 in the trucks with DD8 engines.

“In the future, I’ll be going with DD8 engines in Freightliner trucks. The DD8 helps with emissions, there’s no concern for park regens,” says Hall. “I’ve had no complaints from drivers. Mark has been instrumental in helping us to transition to the DD8s. We’re looking to switch over our dump trucks to this engine as there is a need.” The aftertreatment system which cleans out the engine system, cuts down on maintenance and replacement parts, combined with no park regeneration was the deciding factor for Hall in his decision to purchase DD8s in the future.

Hall commented on the convenience of Detroit’s electronic software tools that are used to diagnose operating issues. For example, if a warning light comes on an email is automatically sent to help diagnose the problem through the Detroit Connect Virtual Technician remote diagnostic system. Hall feels they’ve saved 20 hours a year through reduced time in the shop for maintenance and repairs, in addition to the money they’ve saved for the City of Fairfax, which ultimately is used for other funding, such as local schools.

To learn more about the fleet maintenance program and how to get started today, contact Mark Gibson at 856-630-3229.